Bridging the Gap

Designing a biometric sports bra

Wearable technology to capture biometric data like heart rate and respiration isn’t a new concept. However, most of the products in the marketplace are designed for male athletes – something Claire Smith is hoping to change through an undergraduate research project at the University of Idaho.

Currently, most wearable data collection devices are focused on the chest area, using a chest band or vest structure with sensors. This creates a problem for female athletes who need to wear sports bras for support. Vests worn over sports bras create too many barriers leading to inaccurate readings for female athletes.

Joshua Bailey, an assistant professor in the Department of Movement Sciences, brought the problem to Lori Wahl, senior instructor in the Margaret Ritchie School of Family and Consumer Sciences. Wahl knew Smith, a senior studying apparel, textiles and design, was looking for a project that involved problem solving and had an interest in combining technology and apparel.

“So, the issue I had to solve was, how do we make a sports bra that has biometric sensors in it and make it adjustable so that it fits female athletes,” Smith said.

Collaborating Across Campus

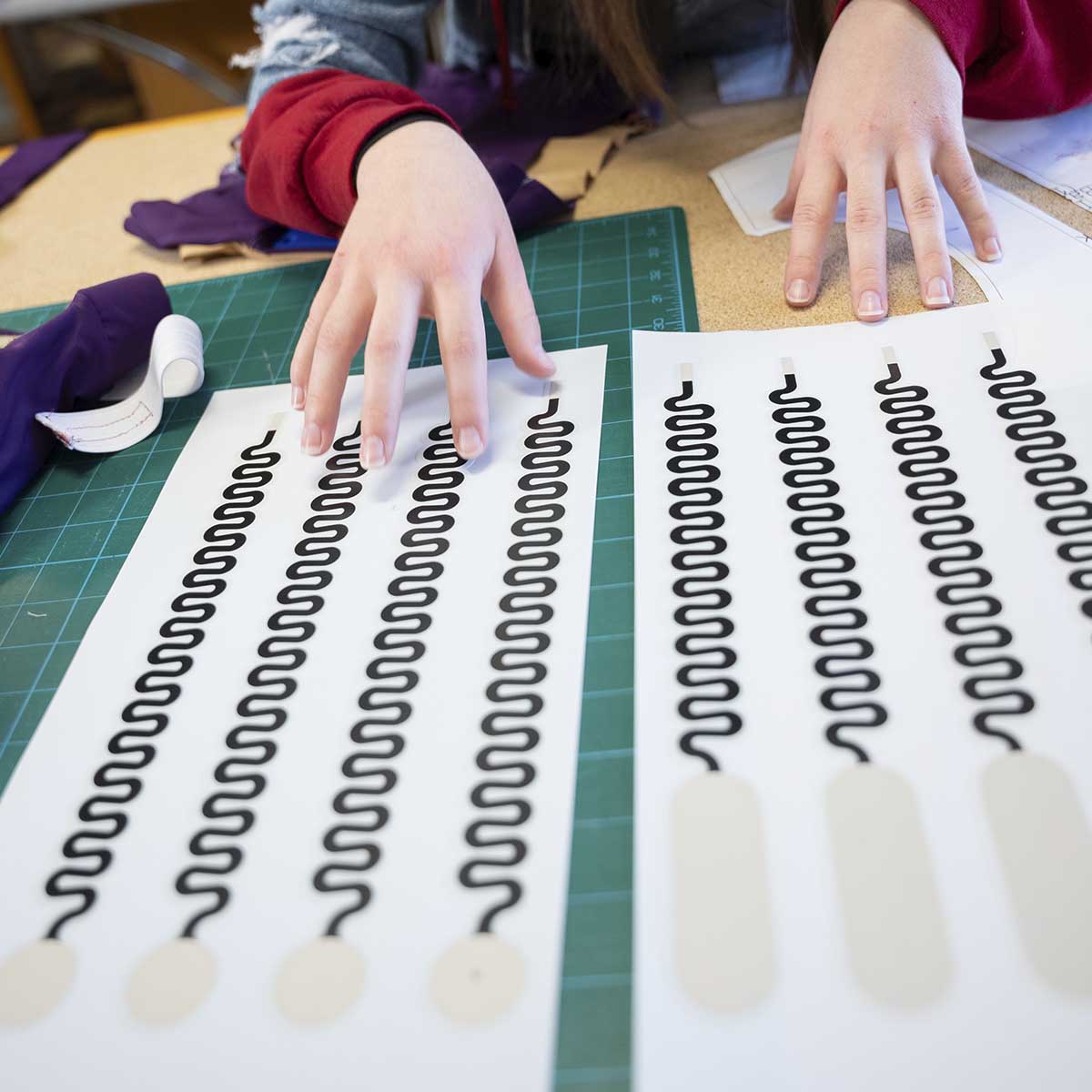

Smith recruited Vandal volleyball players as her models and began making digital patterns and prototypes, gathering feedback from the players about comfort and fit. Soon she had a prototype that included an adjustable chest band where the sensors were embedded. When the band is adjusted the wires move and stretch as needed.

“The patternmaking for the sports bra is easy,” she said. “It’s not the actual pattern that’s the challenge, it’s figuring out how to get those biometric sensors in correctly so we can get those accurate measurements.”

However, what started as a relatively simple project to design an adjustable sports bra with space for biometric sensors quickly escalated once Smith realized she needed help accessing the data she was collecting. Wahl suggested she reach out to James Frenzel, associate professor in the Department of Electrical and Computer Engineering.

“It went from a tiny little project trying to make a sports bra to where now we’re involving our third department,” Smith said.

Frenzel brought the project to Kellen West, a junior studying electrical engineering, who agreed to join the team to figure out the technical components.

“When I came here, one of the major things I wanted to do was work with other departments,” Smith said. “I was told this is a research university, so a lot of people are collaborating and working together. I’m excited to be creating this and working together to come up with solutions to problems we didn’t know we’d have.”

West has developed code that will transfer data from the motherboard located in the back of the bra to a small SD card that can then be transferred to a computer.

“It’s been really fun to try out something that’s not part of the curriculum,” Smith said. “I’ve been left to my own devices and so I’m allowed to play and it’s fun to stretch those skills and work them in a way that will, down the line, be really helpful in a professional setting.”

Bridging the Gap

CALS student Claire Smith designed a sports bra for gathering biometric data as part of an undergraduate research project.

Adaptive Apparel

Originally from Genesee, Smith graduated in May 2024 and is planning to pursue a master’s degree in family and consumers sciences at U of I. She’d like to either continue her research into wearable technology or explore her interest in adaptive apparel. She developed a line of adaptive business apparel for people with upper body impairments as her senior capstone project.

“A lot of adaptive apparel is designed for those with lower body impairments, like pants with buttons on the side, zippers and Velcro,” she said. “I noticed that those with upper body impairments, like missing arms or limited use of their arms or upper body didn’t have as many options.”

Smith reached out to the U of I Center for Disability Access and Resources who put her in contact with students willing to speak with her about their impairments and the issues they have when trying to find apparel. One of the students mentioned the lack of professional attire available.

“A lot of the options were baggy or casual clothing,” Smith said.

Smith developed several concepts and asked the students for feedback. She discovered that denim was a non-starter because of the lack of stretch. Some of the students she spoke with require the use of tools like industrial hooks to help them dress, so fabrics with stretch and give were essential.

She created a line that consists of a jacket with button up magnetic closures and arms that can be cinched, shirts with stretch bodices, and pants that feature thicker belt loops and horizontal loops to make them easier to pull up. She also incorporated rubber filament panels that use friction to further help pull up the pants.

For Smith, working on projects like the biometric bra and adaptive apparel allows her to flex her problem-solving skills.

“I love problem solving,” she said. “This is why I came to this university. I wanted that experience and sense of interconnection and learning about our differences and working through them.”

Funding for the biometric bra project provided by the U of I Office of Research and Economic Development OUR Research Grant program, Department of Electrical and Computer Engineering and the Margaret Ritchie School of Family and Consumer Sciences.

Article by Amy Calabretta, College of Agricultural and Life Sciences

Photos by Rio Spiering, Visual Productions

Published in May 2024